Energy Saving Industrial Boiler Gas Fired Steam Boiler Coal Burning Steam Generator Hot Water Heater for Textile Mill and Food Processing Plant

energy saving industrial boiler gas fired steam boiler coal burning steam generator hot water heater for textile mill an

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | WNS |

| Specification | different model, different size |

| Trademark | Sinoder |

| Origin | China(Mainland) |

| HS Code | 8402120090 |

| Production Capacity | 500sets/Month |

Product Description

energy saving industrial boiler gas fired steam boiler coal burning steam generator hot water heater for textile mill and food processing plantProduct Description:

Oil gas steam boilers require the use of a burner to inject fuel into the boiler hearth, which is burned in a fire chamber without the use of grate facilities. Since the fuel gas boiler does not produce fuel ash after combustion, the fuel gas boiler does not need to discharge the slag facility. If the oil and gas injected into the furnace are mixed or extinguished within a certain range with the air, it is easy to explode. Therefore, fuel gas boilers require an automated combustion and control system. The fuel gas boiler is compact in structure, and the small boiler body and its ventilation, water supply, control and auxiliary equipment are all arranged on one distribution box, and the large and medium-sized ones can also be assembled.

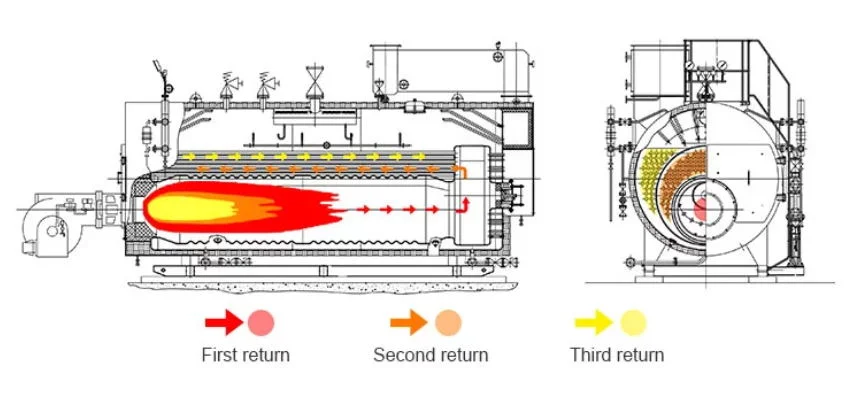

Burning Priciple of Oil Gas Boiler:

The design and manufacture of WNS horizontal steam boiler body adopts three-return, wet-back type, eccentric hearth, asymmetric structure, corrugated furnace, which makes the flame generate strong disturbance, and increases the radiation heating surface, which greatly enhances the heat transfer coefficient. It can effectively prevent the life of the equipment from decreasing due to thermal expansion and contraction of the metal.

Features and Advantages:

1. The boiler adopts a three-return horizontal wet-back structure, and the butt joints are welded to improve the reliability of the boiler.

2. Use a threaded pipe with high heat transfer coefficient to enhance the convective heat transfer effect, reduce the exhaust gas temperature, and improve the thermal efficiency of the boiler.

3. The combustion chamber adopts full corrugated furnace structure, which has good flexibility and strong resistance to external pressure; strong turbulence, good disturbance, enhanced heat transfer and high thermal efficiency. It also increases the heated area.

4. The large volume and low position layout design of the boiler combustion chamber not only improves the combustion efficiency of the fuel, but also increases the safe water level range in the boiler, and minimizes the possibility of accidents due to lack of water.

Company Information:

Our company specializes in the production of gas steam boilers such as natural gas boilers and fuel gas boilers. There are also gas hot water boilers, gas heat conduction oil furnaces, gas hot air furnaces, gas organic carrier furnaces, gas vacuum boilers, vertical gas boilers, biomass steam boilers, biomass hot water boilers, biomass hot blast stoves, biomass heat transfer oils. Furnace and other products. Our products are widely used in electric power, machinery, metallurgy, chemical, textile, paper, food, industrial, washing, building formwork, drying, heating, hot water, bathing and other fields.

FAQ:

1. What are the available fuel for the oil gas fired boiler?Oil gas fired boiler could burn both liquid fuel and gaseous fuel. The liquid fuel could be heavy oil, light oil, diesel, furnace oil, bunker oil, LPG (liquefied petroleum gas), etc. The gaseous fuel could be natural gas, city gas, bio-gas, etc.2. Whether the boiler can burn dual fuel or multi-fuel?Sitong boiler have oil burner, gas burner, and oil&gas dual fuel burner, we can offer the specific burner based on customers' requirement.3. What is the thickness of combustion chamber?the thickness of corrugated furnace is different based on working pressure and furnace diameter, generally, the thickness is between 10~18mm, large combustion space, and combustion sufficient.4. What is the inlet pressure of gas burner?The inlet gas pressure is different for different capacity boiler, for example, the pressure for 2 ton steam capacity boiler is about 8~10KPa, while for 4 ton steam capacity boiler is about 18~20KPa.

For more information,welcome to contact us freely:

Related Products

-

![Full Automatic Water Tube Fuel Oil Gas Steam Boiler Vertical Gas Powered Generator 3 Phase Hot Sale]()

Full Automatic Water Tube Fuel Oil Gas Steam Boiler Vertical Gas Powered Generator 3 Phase Hot Sale

-

![China Factory 20kw Home Heating and Hot Water Wall Hung Gas Combi Boiler]()

China Factory 20kw Home Heating and Hot Water Wall Hung Gas Combi Boiler

-

![Energy Saving Environment Friendly Waste Heat Boiler with Evaporator & Economizer]()

Energy Saving Environment Friendly Waste Heat Boiler with Evaporator & Economizer

-

![China Alva Machine Waste Heat Boiler/Steam Generator/Steam Boiler/Boiler/Chain Grate Boiler]()

China Alva Machine Waste Heat Boiler/Steam Generator/Steam Boiler/Boiler/Chain Grate Boiler