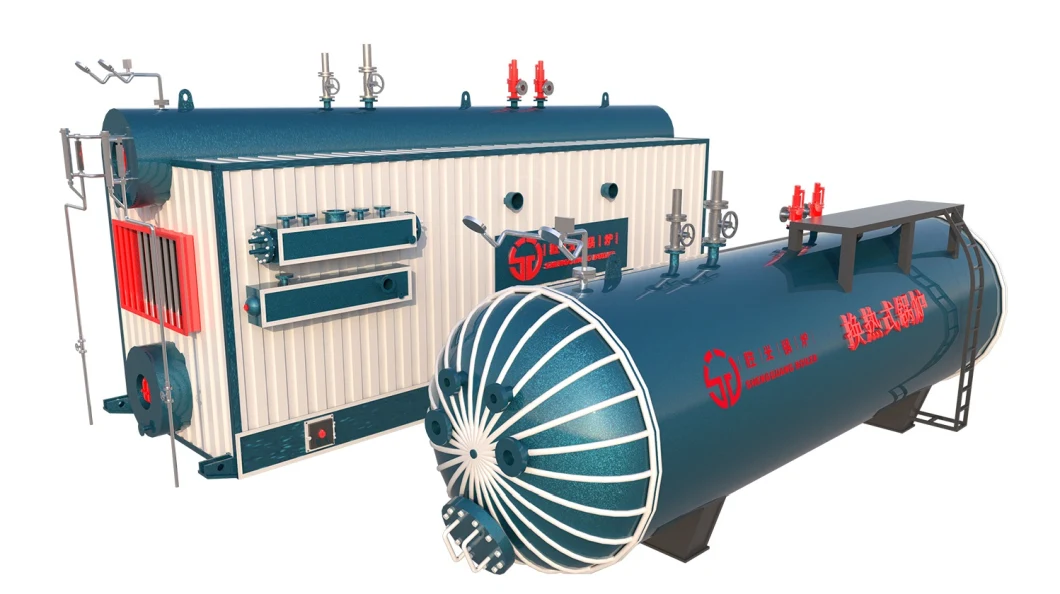

Customized High-Tech Waste Heat Recovery Boiler

Customized high-tech Heat recovery boiler Rated capacity :1-20ton/hr Design pressure :1.0Mpa (10bar/10kg/145psi) 1.25Mpa

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | Waste Heat Recovery Boiler |

| Drum Placement | Horizontal Boiler |

| Pressure | Low Pressure |

| Manufacturing Level | A |

| Burning Style | Chamber Combustion Boiler |

| Usage | Industrial, Power Station, Textile Industry |

| Manufacturer | Yes |

| Rated Evaporation Capacity | 1-20 T/H |

| Rated Working Pressure | 0.7/1.0/1.25MPa |

| Rated Steam Temperature | 170/184/194 ºC |

| Water-Supply Temperature | 20/60/105ºC |

| Transport Package | Standard Shipping Package |

| Specification | wood pellet boiler |

| Trademark | Shengli Boiler |

| Origin | China |

| HS Code | 8402190000 |

| Production Capacity | 200sets |

Product Description

Customized high-tech Heat recovery boiler

Rated capacity :1-20ton/hr

Design pressure :1.0Mpa (10bar/10kg/145psi) 1.25Mpa(13bar/13kg/180psi) 1.6Mpa(16bar/16kg/232psi)

Steam temperature: 184ºC 194ºC 204ºC

Strong applicability and extensive use.

- Our company can provide users with standardized waste heat boiler, but also customized one according to users' different needs with rich experience in designing corrosion-resistant and wear-resistant pipelines. It can be designed separately for high sulfur, high ash, low temperature and high hardness flue gas.

- The different designed waste heat boilers can transfer the required heat to users through saturated steam, superheated steam, organic heat carriers, hot water and other heat conducting media. It is widely used in power generation, petroleum, chemical industry, building materials, metallurgy, carbonization and other industries.

System diagram of single-drum Biomass and coal fired Boiler

Compact structure, easy installation.

- The waste heat boiler is compact in structure, small in volume.

- Fast-assembly structure, easy to install on site.

Simple operation and easy maintenance.

- Automatic water replenishment , easy operation.

- Easy to maintain, low maintenance costs.

According to their different structures, they can be divided into following types:

1.hot tube waste heat boiler 2.pin type waste heat boiler 3.waste heat boiler for generator sets 4&5.exhaust flue gas fired waste heat boiler

and also finned tube waste heat boiler, EGB threaded tube waste heat boiler, bare tube waste heat boiler, shell type waste heat boiler and etc.

Technical Parameters

| Waste heat boiler belongs to non-standard product, which usually needs to be calculated and designed according to the parameters provided by customers. Generally speaking, the design pressure of non-combustion waste heat boiler is 0.2-2.5 Mpa, the working pressure is 0.4-2.5 Mpa, and the steam output is 0.2-25 t/h. Some waste heat boiler technical parameters as following: | ||||

| Specification | Q5-940-2-1.0 | Q16-900-6-1.25 | Q20-1050-9-2.5 | Q32-800-11-1.6 |

| Rated evaporation capacity(t/h) | 2 | 6 | 9 | 11 |

| Rated working pressure(MPa) | 1 | 1.25 | 2.5 | 1.6 |

| Rated steam temperature(ºC) | 184 | 250 | 226 | 204 |

| Water-supply temperature(ºC) | 20 | 20 | 125 | 20 |

| Inlet flue gas flow rate(Nm³/h) | 5000 | 16000 | 20800 | 32000 |

| Inlet flue gas temperature(ºC) | 940 | 900 | 1050 | 800 |

| Outlet flue gas temperature(ºC) | 385 | 164 | 371 | 179.9 |

| Heating area(m2) | 171.79 | 536.1 | 345 | 916.6 |

| Boiler Installation Size L×W×H (mm) | 6200×3440×8419 | 8035×3500×4390 | 12262×2680×4860 | 10500×3050×4150 |

If you want a waste heat boiler pls try to provide the following parameters:

| A | Its industry | |

| B | Flue gas parameters | |

| 1 | Boiler inlet flue gas side pressure | |

| 2 | Boiler inlet flue gas range (operating conditions) | |

| 3 | Range of boiler inlet flue gas (standard condition) | |

| 4 | Design value of boiler inlet flue gas (standard condition) | |

| 5 | Boiler inlet flue gas temperature range | |

| 6 | Design value of boiler inlet flue gas temperature | |

| 7 | Boiler outlet flue gas temperature | |

| 8 | Boiler inlet flue gas composition (volume percentage) | |

| CO | ||

| SO2 | ||

| SO3 (if any) | ||

| CO2 | ||

| H2O | ||

| O2 | ||

| N2 | ||

| HCL (if any) | ||

| Other special gases | ||

| 8 | Boiler inlet flue gas dust concentration | |

| Boiler inlet flue gas adhesion | ||

| Corrosiveness of boiler inlet flue gas | ||

| 9 | Required resistance on the flue gas side of the boiler body | |

| 10 | Total air leakage requirements on the boiler flue gas side (if any) | |

| C | Boiler parameters | |

| 1 | Boiler rated steam (if any) | |

| 2 | Boiler rated steam pressure | |

| 3 | Boiler rated steam temperature | |

| 4 | Boiler feedwater temperature | |

| D | Other required parameters | |

| 1 | Elevation and size of smoke exit of industrial furnace | |

| 2 | Elevated smoke outlet elevation of waste heat boiler | |

| 3 | Waste heat boiler is expected to occupy land (length m × width m × height m) | |

| 4 | Does the waste heat boiler need to be supplied by the manufacturer to support the top rain shelter? | |

| 5 | Boiler layout (vertical or horizontal layout) | |

| 6 | Owned plant's own compressed air pressure | |

| 7 | Whether the owner's plant has its own natural gas source | |

| 8 | Meteorological conditions at the owner's plant (mainly local atmospheric pressure and seismic fortification intensity) | |

| E | Auxiliary machine | |

| F | Other special requirements |

CERTIFICATE

Class A Boiler manufacture, Design Licence of special equipment,

Class A Manufacture License of special equipment, Installation Repair and Maintenance License of special equipment, OHSAS18001, ISO9001, ISO14001, DOSH

FAQ:

Q: Are you manufacturer?

A: Yes, we are manufacturer. Our factory established in 1978 in Pingdu Qingdao.

Q:How to choose a boiler type ?

A: Generally we should confirm the boiler type (steam or hot water),capacity,pressure(or output,temperature)and fuel(coal, biomass, gas or oil) of the boiler.

Q: How long is the warranty time for the boilers?

A: Based on highly responsible for your esteemed company, due to equipment itself failure, our company provides one year free maintenance.

Q: How about the installation ?

A:We could offer you 2 proposals.

1)Guide installation

Our company arranges 1-2 staffs to guide the installation of boiler on site , fully guarantee the installation quality.

2)Staff installation

Our company is in charge of installation process, only your company to provide accommodation, round-trip cost and pay the wages of workers.

Q: Could you offer some wear parts?

A: Our company provides a set of tools for free, such as wrench ,gasket used for Convenient maintenance.

Q: What's your MOQ?

A: 1 set, if you purchase more, you will get a fairly favorable price.

Q: Do you have any Certificate?

A: Yes. We have ISO9001 & ISO14001 certificate. If must,we could help you get CE ASME or AS certificate.

Q: What is your payment term ?

A: T/T, L/C is very well used .

Related Products

-

![China Boiler 0.5 - 10ton Natural Gas GLP LPG Diesel Bunker Fuel Oil Fired Steam Boiler Price]()

China Boiler 0.5 - 10ton Natural Gas GLP LPG Diesel Bunker Fuel Oil Fired Steam Boiler Price

-

![300kg/H 500kg/H Diesel Oil Fuel Laundry Small Horizontal Vertical Industrial Automatic Water Electric Gas Steam Boiler]()

300kg/H 500kg/H Diesel Oil Fuel Laundry Small Horizontal Vertical Industrial Automatic Water Electric Gas Steam Boiler

-

![Coke Oven Exhaust Gas Waste Heat Recovery Boiler for Sale]()

Coke Oven Exhaust Gas Waste Heat Recovery Boiler for Sale

-

![China Szw 4, 6, 8, 10, 12, 15, 20, 25 Tons Biomass Pellet Rice Husk Corn COB Wood Chips Sawdust Bagasse Fired Industrial Step Grate Water Tube Steam Boiler]()

China Szw 4, 6, 8, 10, 12, 15, 20, 25 Tons Biomass Pellet Rice Husk Corn COB Wood Chips Sawdust Bagasse Fired Industrial Step Grate Water Tube Steam Boiler